PCB Board Maker Can Be Used in Flexible Gas Sensors

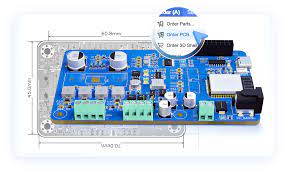

The environment is filled with invisible gases that may be harmful, useful or deadly. Detecting these chemicals is critical for medical devices, industrial processes, home safety and more. At the heart of every gas sensor is a purple printed circuit board (PCB). This key component converts chemical detections into electronic signals that can be interpreted and acted upon.

The first step in creating a PCB is designing a circuit diagram that shows the components and how they connect to each other. This process is time consuming and it’s important to take the right steps to avoid losing all those hours of hard work. To help, there are online services that can generate a PCB design for you and make the entire process much faster and easier.

These online services can also be used to create prototypes of your product. They offer a variety of PCB types, including flexible and rigid boards, so you can test out your concept in real life. They will also help you find the best materials for your project and recommend the correct type of fabrication.

Once you’ve created your circuit diagram, the next step is to turn it into a physical prototype. This is where a pcb board maker comes in handy. A pcb board maker can convert your virtual design into industry standard CAM outputs for professional manufacturing, including Gerber and NC Drill files. It can also produce IPC test point reports and other necessary documentation for professional assembly.

How a PCB Board Maker Can Be Used in Flexible Gas Sensors

A pcb board maker can also help you save money by cutting out middlemen and buying directly from the manufacturer. Purchasing direct allows you to get better pricing and fast turnaround times. In addition, it will also help you reduce your carbon footprint by avoiding unnecessary shipping. Many reputable manufacturers also provide around-the-clock tech support, so you can always receive assistance when you need it.

In addition to reducing your costs, partnering with an American pcb manufacturer will help you support local employment and strengthen the economy. It will also help you achieve your production goals while remaining competitive in today’s ever-changing market. By partnering with an American pcb producer, you can be sure that your products will live up to the highest standards.

The main thing you need to consider when choosing a pcb board maker is the amount of copper used in the board’s construction. You should be aware that the price of raw copper varies daily and may affect your total bill. In addition, the pcb board maker should use high-quality components and have a high quality control process in place. This will ensure that your pcb is both durable and reliable in the harsh environments where it’ll be placed. In addition to this, the pcb should be free of any flaws that can negatively affect its functionality. It should also be resistant to moisture, humidity, and dust. Finally, the pcb should be able to withstand repeated soldering and high temperatures.