Challenges Faced During Board Assembly

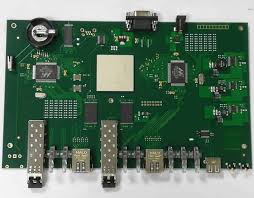

A printed circuit board (PCB) is the brains of electronic devices, connecting components together to collectively do their “work”. In order for a PCB to function properly, it must be assembled to the highest standards. The good news is that assembly defects can be avoided with careful planning and attention to detail during the design and fabrication stages of a project. However, assembly defects can still occur due to a variety of factors. These include:

As the current global chip shortage continues, many manufacturers struggle with component availability and production delays, making it challenging to keep up with demand while ensuring quality. Manufacturers can mitigate the impact of these supply chain problems by working with a trusted ECM that offers a diverse set of sourcing options and an extensive inventory. Additionally, manufacturers can reduce assembly headaches by vetting parts for suitability during the bill of materials review process.

It’s important to have clear and effective assembly instructions. This is the best way to prevent mistakes and misunderstandings, which can lead to misalignment, missing parts, and unfinished connections. To improve assembly instructions, encourage open communication between staff and supervisors who have firsthand experience with the process. This feedback can be invaluable in identifying ambiguities or steps that are prone to error, and it’s also a great source of ideas for continuous improvement.

Common Challenges Faced During Board Assembly

It is nearly impossible to assemble surface-mount components by hand without the right machinery. Unlike their thru-hole counterparts, which are inserted through holes drilled into the PCB and soldered to pads on the opposite side, SMT components have smaller leads and a matrix of solder balls arranged in a ball grid array (BGA) underneath them that require specialized machinery for proper placement. If a BGA isn’t placed correctly, it can short out the entire board or cause it to malfunction.

Soldering defects are a common issue that can be difficult to correct. These errors can be caused by a number of factors, including inappropriate equipment, insufficient flux usage, and inadequate cleaning before soldering. In addition to the physical damage that they can cause, these defects can also impact performance. Used primarily for THT, the board assembly is passed over a wave of molten solder, which coats the exposed metal areas and forms a bond with the component leads.

Ultimately, it’s up to designers to create PCBs that are production-ready before sending them to the manufacturer. During the DFM process, design engineers should always consider manufacturability, focusing on the layout’s ability to meet manufacturing requirements. By incorporating the best manufacturing practices into a design, the chances of a defect are significantly reduced.

While assembly defects are inevitable, they can be minimized with a solid plan and a trustworthy partner. To ensure that your PCBs are built to the highest quality, work with an ECM who offers a comprehensive QA program. Whether it’s boundary scan, in-circuit test or flying probe, an ECM that uses advanced technology can help eliminate quality defects and ensure a smooth assembly process. In the end, this will save you time and money while delivering high-quality products to your customers.