Can an electronics assembly be used

Electronics assemblies play a crucial role in the telecommunications industry, providing the backbone for various equipment used in transmitting, receiving, and processing information. From smartphones and base stations to routers and satellites, telecommunications equipment relies heavily on sophisticated electronics assemblies to ensure seamless communication across vast distances.

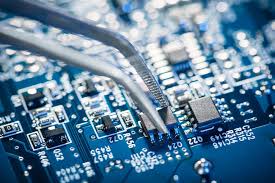

One of the primary applications of electronics assembly in telecommunications is in network infrastructure. Core network components, such as routers, switches, and gateways, are built on complex PCBs (Printed Circuit Boards) that house multiple integrated circuits, processors, and memory modules. These components are assembled using advanced techniques like Surface Mount Technology (SMT) to achieve high density and reliability. These assemblies ensure data packets are efficiently routed and switched, maintaining the integrity and speed of data transmission across networks.

Base stations, which are essential for mobile communication, also depend on high-performance electronics assemblies. These stations contain radio transceivers, power amplifiers, and signal processing units, all of which are integrated on PCBs. The precision and reliability of these assemblies are critical as they handle high-frequency signals and manage multiple communication channels simultaneously. Advanced techniques such as Ball Grid Array (BGA) assembly and flip chip technology are often employed to enhance the performance and durability of these components, ensuring they can withstand the demands of continuous operation and varying environmental conditions.

Can an electronics assembly be used in telecommunications equipment?

In addition to infrastructure, electronics assemblies are integral to user-end devices like smartphones and tablets. These devices include a variety of components, such as processors, memory, sensors, and communication modules, all assembled on compact PCBs. The miniaturization and integration of these components are achieved through advanced manufacturing processes, enabling devices to offer a wide range of functionalities while maintaining a small form factor. This is particularly important in telecommunications, where the demand for more features and better performance continues to grow.

Telecommunications satellites, which provide coverage to remote areas and facilitate international communications, are another area where electronics assemblies are indispensable. Satellite electronics must be highly reliable and capable of operating in harsh space environments. Components used in satellites undergo rigorous testing and are assembled using techniques that ensure they can withstand extreme temperatures, radiation, and the vacuum of space. Conformal coating and encapsulation are often used to protect these assemblies from environmental stressors, enhancing their longevity and reliability.

Moreover, electronics assemblies are crucial in the development and deployment of 5G technology. 5G networks require advanced hardware capable of supporting higher data rates, lower latency, and increased device connectivity. This involves the integration of sophisticated RF (Radio Frequency) components, antennas, and signal processing units on PCBs. The precision and performance of these assemblies are paramount as they directly impact the efficiency and effectiveness of 5G networks. Techniques such as high-frequency PCB design and advanced soldering methods are employed to meet the stringent requirements of 5G telecommunications equipment.

Another critical aspect of using electronics assemblies in telecommunications is the need for robust testing and quality assurance. Equipment used in telecommunications must comply with various standards and regulations to ensure reliability and interoperability. Automated Optical Inspection (AOI), In-Circuit Testing (ICT), and functional testing are essential to identify and rectify defects during the assembly process. These testing methods ensure that the electronics assemblies perform as expected and can handle the rigorous demands of telecommunications applications.

In conclusion, electronics assemblies are fundamental to the functionality and reliability of telecommunications equipment. From network infrastructure and base stations to user devices and satellites, these assemblies enable the efficient and effective transmission of data across global communication networks. Advanced manufacturing techniques and rigorous testing processes ensure that the assemblies meet the high standards required in the telecommunications industry, driving the continuous advancement and expansion of global communications capabilities.